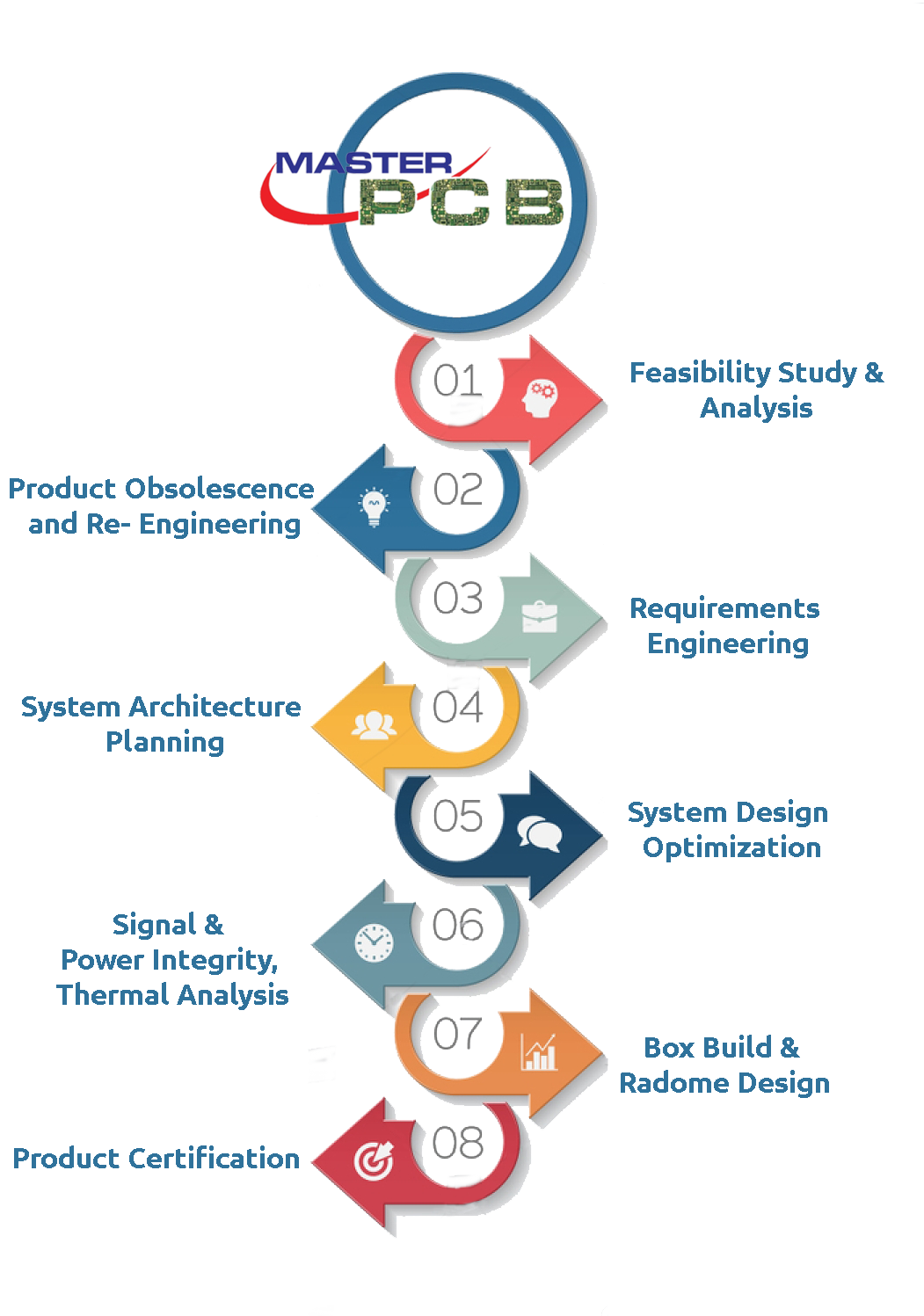

MASTERPCB Offers complete end-end System engineering solutions to our customers covering the following.

Feasibility Analysis

Before initiating any project or product, MASTERPCB will analyse and understand the complete system requirement and does the feasibility study analysis and prepare a methodology to assess and evaluate whether the consolidation of the instances would be technically feasible and be economically feasible. The methodology leverages MASTERPCB experience in delivering such solutions to clients globally on such strategic engagements for advising our clients for such programs on consolidation.

At Master PCB we will be transparent to our customers in every stage of the feasibility and provide the appropriate feedback about the Scope, Issues and the associated business risk with the product/project. This would enable our customers to understand the risk and corresponding mitigation plans to make the sustainable and profitable investment.

Product Obsolescence and Re- Engineering

Hardware components become obsolete every few years. This necessitates re-design using components currently available in the market. MasterPCB with its ecosystem partnerships with leading semiconductor companies is uniquely positioned to re-design with components which are not likely to become obsolete in the near feature.

MasterPCB has been equipped with the necessary expertise, tools and systems to redesign or reverse engineer the complete product including electrical, mechanical & electronics functions in support of through-life and obsolescence management to keep your products and systems operating when original components are no longer available. Our services include complete redesign from scratch, sub-system or component redesign, re-creation of drawings and documents from existing product/items and manufacture based on old product or the limited documentation available to customer.

MASTERPCB’s system engineering team support customers globally in the area of Electrical, Electronics, and Mechanical & Software to provide sustainable engineering support throughout the product cycle time.

The team also provides engineering support for cost reduction, End of life, Re-engineering firmware support. Both the PCB engineers and System engineering teams work with world class EMS facilities worldwide from our ecosystems to provide best in class price-performance solutions.

We also help organizations to re-architect their product/solution using current technologies, which results in efficient products/solutions with extended product life cycle. MasterPCB considers product/solution scalability and flexibility as key design objectives while re-engineering. We also help in extending the product/solution to new areas so as to address a larger market segment.

Requirements Engineering

It’s a process of ensuring the specified requirements meet the customer needs. It’s concerned with finding problems with the requirements. These problems can lead to extensive rework costs when these they are discovered in the later stages, or after the system is in service. The cost of fixing a requirements problem by making a system change is usually much greater than repairing design or code errors. Because a change to the requirements usually means the design and implementation must also be changed, and re-tested.

During the requirements validation process, different types of checks should be carried out on the requirements. These checks include:

Validity checks: The functions proposed by stakeholders should be aligned with what the system needs to perform. You may find later that there are additional or different functions are required instead.

Consistency checks: Requirements in the document shouldn’t conflict or different description of the same function

Completeness checks: The document should include all the requirements and constrains.

Realism checks: Ensure the requirements can actually be implemented using the knowledge of existing technology, the budget, schedule, etc.

Verifiability: Requirements should be written so that they can be tested. This means you should be able to write a set of tests that demonstrate that the system meets the specified requirements.

There are some techniques you can use to validate the requirements, and you may use one or more of them together, depending on your needs.

Requirements Reviews: A team of system customer; those who interact with the customer to gather requirements, and system developers start reading the requirements in the document, and investigate in a great detail to check for errors, inconsistency, conflicts, and any ambiguity. Then they may negotiate with the customer on how to solve the problems and errors found.

Prototyping: We’ve discussed the prototyping as one of the (non-standalone) software process methodology, which used as part of full methodologies, and we’ve also mentioned in can be used in the requirements engineering. In this approach to validation, an executable model of the system is demonstrated to the customer and end users to validate, and ensure if it meets their needs. Prototyping is usually used when the requirements aren’t clear. So, we make a quick design of the system to validate the requirements. If it fails, we then refine it, and check again, until it meets the customer needs. This definitely will decrease the cost as a result of having a clear, understandable, consistent requirement.

Test-case Generation: As we’ve just mentioned, the requirements need to be testable. If the tests for the requirements are added as part of the validation process, this often reveals requirements problems. If the test is difficult or impossible to design, this usually means that the requirements will be difficult to implement and should be reconsidered.