We cater to multiple market segments with mechanical and electro-mechanical engineering services and as a result our capabilities have expanded over the years. Our mechanical team can design test fixtures, customized test cells and develop products. Not to mention the easy validation of design modifications before building any physical prototypes.

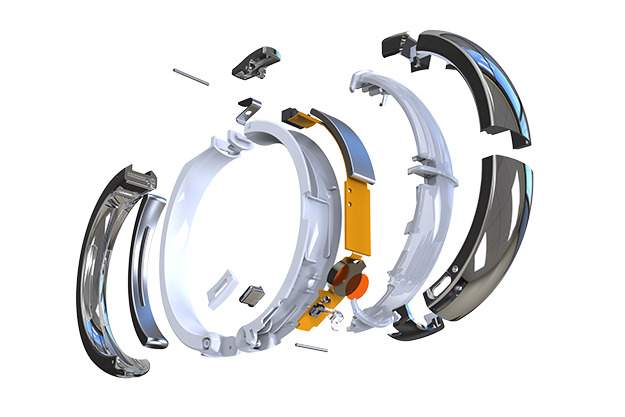

Product Design& Development

Our team of engineers will make sure your idea is transformed into a genuine product. Our assistance does not just stop with product design, we prototype real time, support your production, supply chain and marketing needs.

Highlights:

- Concept Generation

- Reverse Engineering

- Detail Design

- Manufacturing Drawings

- Bill of Materials

- Product Rendering & Animation

- Assembly Instructions

- Rapid Prototyping

- Pilot

- Production

Product Expertise:

- Hydraulic Actuators, Industrial Valves, Cryogenic Valves, Control Valves & Knife Gate Valves per API and ASME.

- Telecom RF Products like Repeaters, Remote Radio Heads (RRH), Antennas, Filters and TMAs.

- Telecom Towers, Cell on Wheel, Mobile Deployment Towers and Telescopic Towers.

- Shelters, Enclosures, Cabinets, Racks and Shelves for Indoor and out door applications.

- Special purpose machines & Material handling equipment.

- MEP & HVAC.

- Printed Circuit Boards (PCB) and Assemblies.

3D Modelling & Drafting service

While your engineer or management focus on key engineering activities, our team help you to create 3D Models, Manufacturing drawings, Engineering Change Orders, Bill of Materials , Product Life Cycle management and other documentation work. Your team can focus on Preliminary concept and we will take it from there and deliver the finished engineering drawings for manufacturing including bill of materials and other supporting documents.

- 2D to 3D conversion

- State Approval Drawings

- Engineering Drawings

- AutoCAD to 3D CAD Conversion

- Legacy Drawing Conversion

- Documentation Support

- Data Entry

Tool Design & Development:

- Our Engineers are skilled in Press tool, Pressure Die Casting, Injection Maudling, Jig and Fixture design and development.

- We work with our partners across India to manufacture various tools based on our design and manufacturing drawings. MASTERPCB takes total responsibility for tool quality and delivery.

- Industries: Automotive, Home Appliance, Agriculture, Aerospace and General tooling.

Product Cost Analysis

We help you to bring your product cost down. Our experts can forecast your product cost even before the drawing creation. Know your product cost before you go too far.

We provide:

- Should Costing for Electro-Mechanical Parts

- Should Costing for Electronics Parts

- Assembly Cost Analysis

- Prototype Cost Analysis

- Production Cost Analysis

- Stage-wise Project Cost Analysis

Industrial Design:

We have Industrial Design experience in designing enclosures/casing and helping customers bring their physical product ideas to market.

- Short design cycles

- Reduced time and cost

- Maximized Design quality ( 3D & 2D )

- Automated design of Assembly lines

- Experience to work with qualified designers and industries best tools

Services:

- Process and lay-out design

- Plant simulation

- Product and tooling design

- Innovation – Design – Validation

- Robot- and movement simulation

- Installation drawings

- Documentation (Manuals)

Concept- to Design:

- Assembly lines

- Mechanical operations equipments

- Manual, semi-automated and automated stations

- Special machines with different functions: screwing, crimping, testing, press fitting, fastening, assembly, etc.

- Hanging

- Main Line Assembly Stations

Design to Drawing:

Integrating electrical design concept, into Mechanical enclosure is challenging aspect in today’s time to market design environment. The PCB parameters are integrated in to Mechanical CAD tool and validated for its correctness.

Drawing to Fabrication:

2D to 3D conversion: Convert your 2D drawings into full parametric 3D models and designs. Harness the intelligence of 3D models to optimize or enhance your product design.

Paper to CAD: Conversion of paper, TIF, PDF or other static drawings to full 3D. We will transfer all notations, tolerances, and related data to your desired platform.

3D CAD Assemblies, Animation and Rendering: We can develop large-scale, complex assemblies with 100s of components and configurations. Animations and rendering can be extremely useful in your marketing and outreach efforts.

Prints for Manufacturing: We can develop detailed drawings and prints for manufacturing with tolerances, generation of Bills of Materials (BOM) directly from your CAD models.

Accuracy: A dedicated engineer separate from the originator checks every drawing, Additional random check done for of the drawings as additional quality measure.

Fabrication-to Customer Delivery:

MASTERPCB is recognized by its customers for its ability to deliver complex programs in short turnaround times with ease.